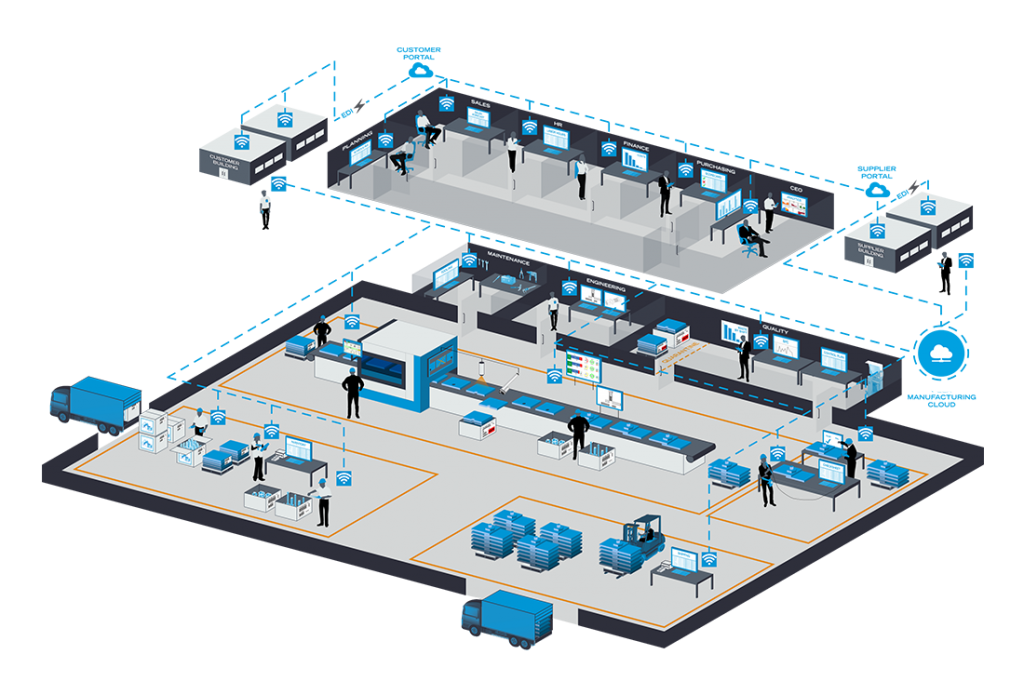

UNIOTEQ is one of the known leader of automation technology. Most reliable semi and fully customized automation in manufacturing unit or production unit design by our mechanical and electrical engineering experts prove us one of the best leader of automation technology in the globe. We as a partner make you feel in ease with our training, service and support.

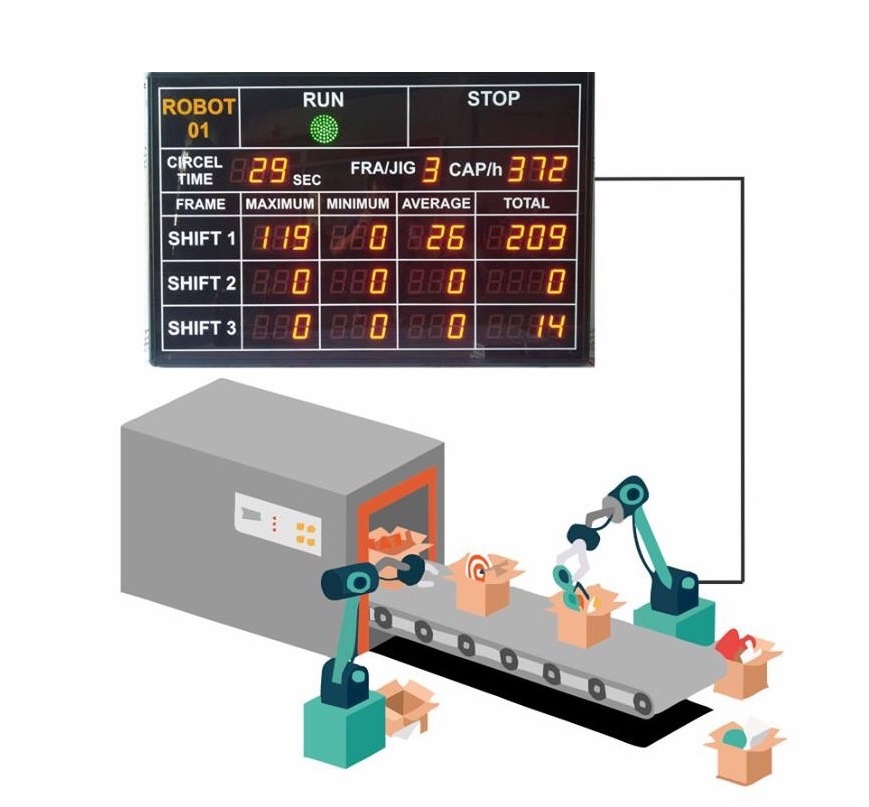

The system provides us the ability to displat conveyor base ststion updates which contains real time up-time and down-time details. The data is further used for analysis of all the different processes and the conditions.

As per the Planning the production can be monitored at any point of time whenever and wherever required. Live status of each critical point on Assembly line will be displayed on independent display screen. Real time production status will be displayed.

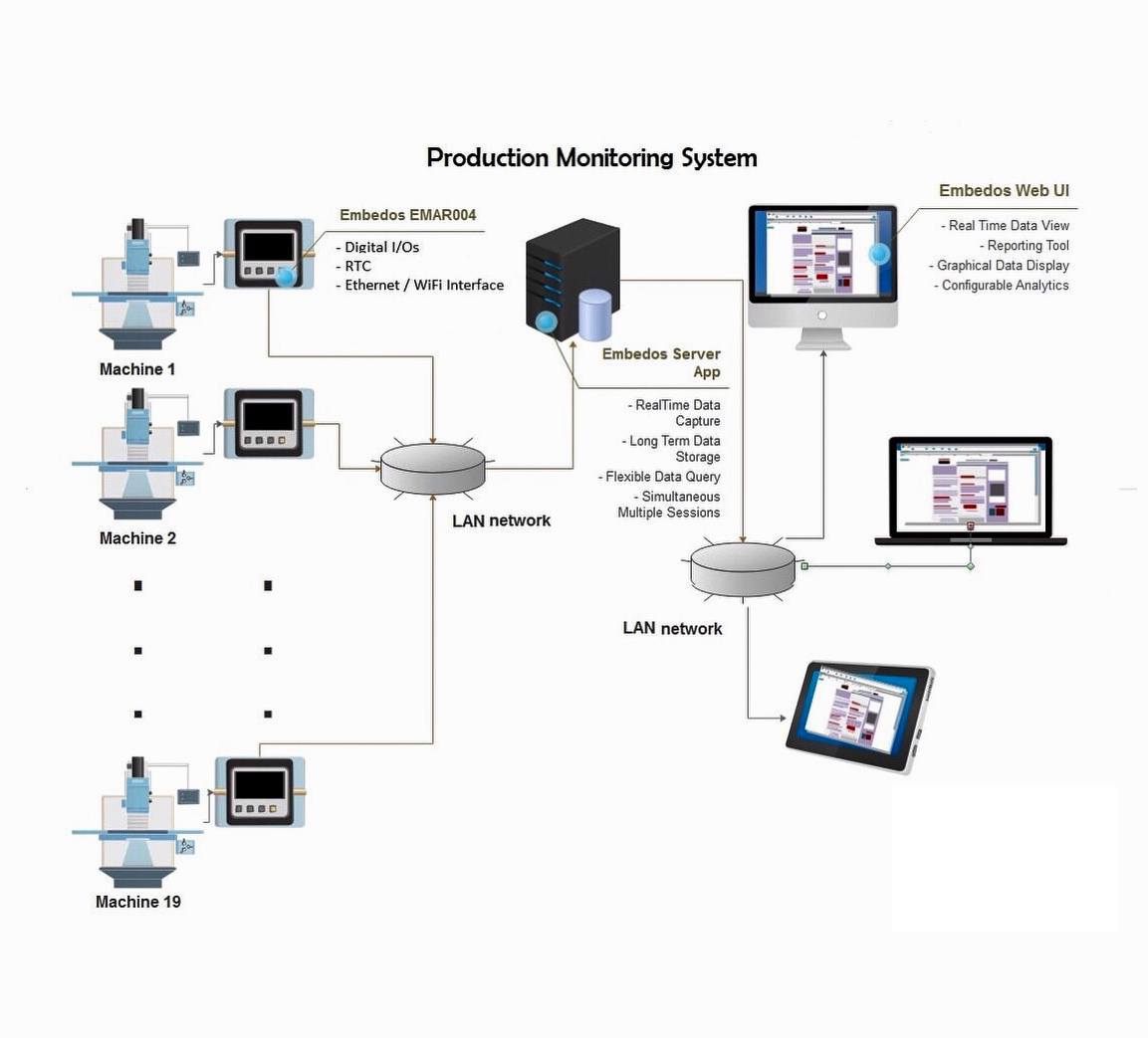

This System will enable the planning of production based on the available inventory and required output, automatically with less human intervention. Uniform production plans will be generated as per the requirement for the production of an engine and will be arranged according to the line/ model/ quantity.

As per the Planning the production can be monitored at any point of time whenever and wherever required. Live status of each critical point on Assembly line will be displayed on independent display screen. Real time production status will be displayed.

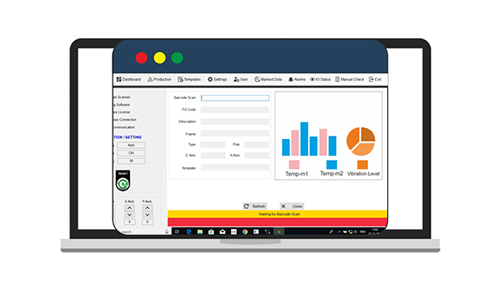

Intelligent sensor in combination with marko-controller and iTRACY makes it possible to collect monitor the data of component and machine or systems in real time. Example like temperature, power and vibration. With the analyzed data we will be able to correct the error and help in reducing the consumption of energy due to fault occurred in the system.

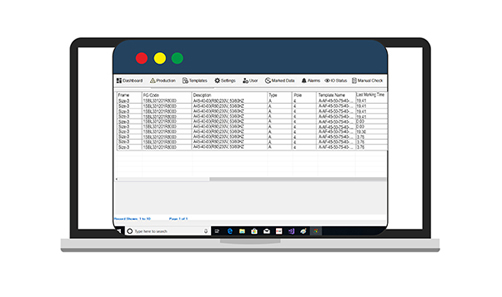

The quality of unique code marked can be scanned and grade is updated to the server if laser marking is done. Managing and tracking the equipment and tools for inspection and the collected data can be integrated to the cloud.

The system provides us the ability to generate reports which contains all the critical data. The data is further used for analysis of all the different processes and the conditions.

Vision Inspection Portal helps in Integration of vision system for vision measurement and color etc. To identify any type of flaw for right inspection and segregation, the integrated vision system helps in easy analysis of production performance.