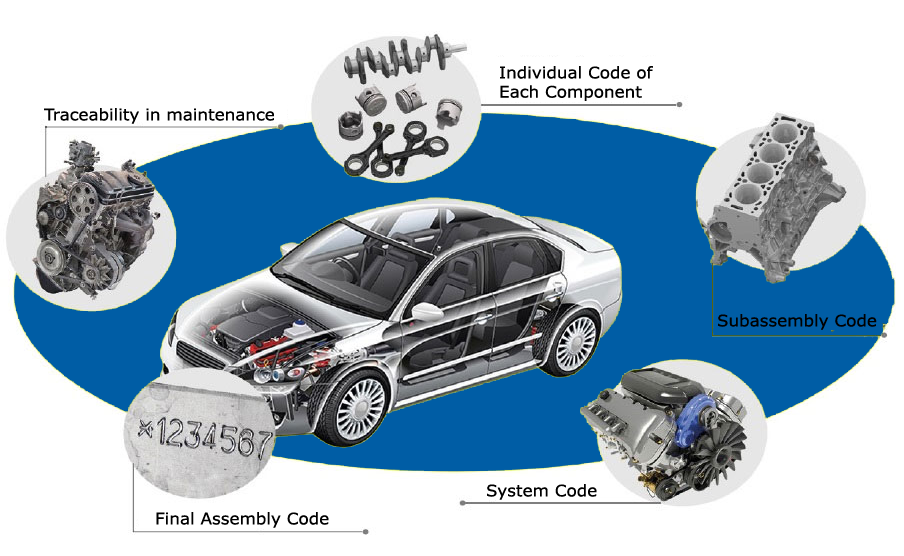

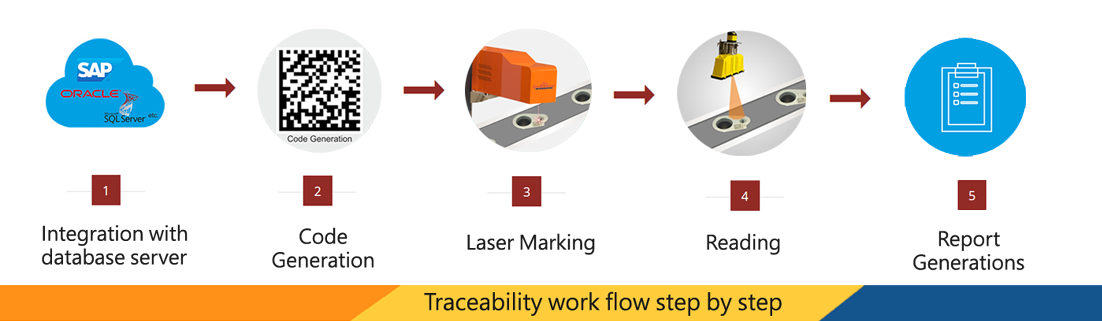

Traceability is an identification system that traces a set of information and is able to verify the history, location, origin, batch number,

time, date, product movement and application of a product or a part by means of documented recorded information.

Traceability explains simple questions like who made the product, when was it made and where was it made.

UNIOTEQ is an end to end Traceability solution provider including software, hardware, automations and integrations

in the manufacturing pipeline of a product.

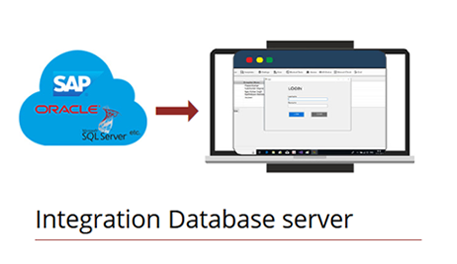

Unioteq gives the capabilities of getting connected with any server or database. The Multiple user accessibility and authentication feature makes it most secure and flexible to use and process the task.

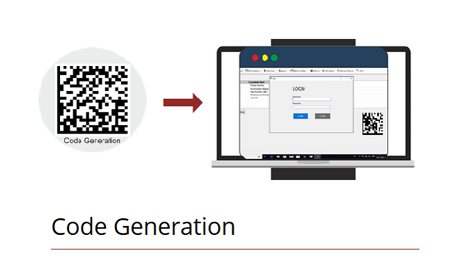

Unique Part Code i.e. UPC is generated and marked is assigned with unique data matrix code, against which the data can be updated and managed.

Laser Marking is done with all compliances so that it can be scanned with any industrial auto scanner or manual scanner, even in harsh environment and condition.

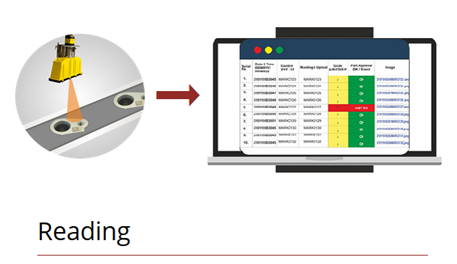

Read UPC data using scanner and logged into database. Production logs helps in identifying the component and trace the data, the grade of 2D data, rejected part in the production processes and uploaded images of 2D code. Built-in analytical tools for quick analysis.

The system provides us the ability to generate reports which contains all the critical data. The data is further used for analysis of all the different processes and the conditions.

To mark a Unique Identity on each and Every component & Track all internal Process

and movement of component against its identity

STEP ONE

STEP TWO

STEP THREE

STEP FOUR

STEP FIVE